Reliable Cooling Options for Industrial Systems’ Heat Management

Control panels, switchgear, and other industrial equipment can avoid overheating by using cooling fans to regulate airflow. They contribute to the protection of vital parts, increase productivity, and observe how electrical and electronic systems function properly in tough scenarios.

Compact fans maintain safe operating temperatures in electronic and electrical devices. They support airflow in enclosed environments and help to prevent overheating and device failure.

.jpg)

They draw in cool air and push out warm air from panels, components, and enclosures. AC fans run on alternating current while DC fans operate using direct current. Both types help regulate heat inside devices and maintain continuous performance under different conditions.

Compact fans come in AC and DC variants to suit different power sources and performance needs. Both options offer multiple sizes, speeds, and blade types.

They are used in systems like server racks, network equipment, control panels, refrigeration units, medical devices, and power supplies. These fans support telecom, optoelectronics, industrial automation, and computer hardware by reducing heat and keeping systems stable.

Choosing the right fan depends on airflow needs, voltage type, and device compatibility. Proper fan selection reduces thermal stress and supports longer equipment life.

Centrifugal Blowers move air through systems that are resistant to ducts, dampers, or filters. They maintain consistent airflow and handle pressure variations in industrial and electrical setups.

They use spinning impellers to add kinetic energy to the air. This energy increases air pressure and pushes the air outward through a curved path. The airflow usually turns at a 90-degree angle as it exits. These fans push a constant volume of air and adapt well to different system demands.

They are used in applications like control panels, UPS, railways, rectifiers, and blow molding machines. These fans support air movement in closed environments and reduce heat without occupying much space.

The blowers come in single-inlet and dual-inlet types. They operate at 50 Hz and are available in 230 VAC and 415 VAC versions.

The right choice of product improves performance and supports safe equipment function. The below factors help to choose the best:

All Metal Compact Fans support airflow in machines and equipment that operate under extreme conditions. These fans control the temperature using high-strength metal components and compact motor designs.

DC/Main Image/Compact Fans - All Metal (AC & DC).jpg)

These fans move air using metal blades connected to external rotor motors. AC models work on alternating current while DC models use direct current. Both types push air through enclosures and cooling paths to remove heat and manage pressure.

Compact all-metal fans are available in both AC and DC versions. The fans use metal housings and impellers to support use in harsh environments.

They are used in UPS systems, welding machines, air conditioning units, power supplies, telecom equipment, and computer servers. These fans help reduce internal heat and keep airflow steady in systems that demand constant cooling.

Select a fan based on airflow demand, voltage type, and system environment. Matching the appropriate fan to your equipment helps manage temperature without interruption.

DC/Compact Fans All Metal (AC).png)

DC/Metal fan Compact AC.png)

External Rotor Motors combine fan and motor into a single compact unit. These motors support cooling and airflow in areas with limited space. They help stabilize temperature and pressure in industrial and electrical equipment.

They use a rotating impeller directly attached to an external rotor. This design reduces bulk and allows better airflow control. These motors operate on alternating current and deliver steady airflow across high-pressure paths.

They are used in HVAC units, UPS systems, blow molding machines, control panels, railways, and power electronics. Their compact size and air pressure performance support cooling inside closed or space-limited systems.

They are available in multiple configurations and support a wide voltage range and come with multiple blade sizes and speed options.

Choose a motor by assessing airflow needs, system layout, and voltage availability. The type of equipment and pressure demands help determine the best model.

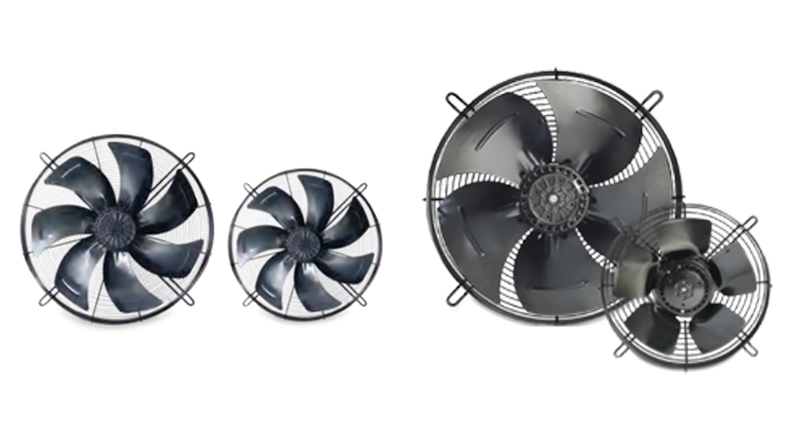

Large axial fans with metal blades support high airflow in machines and enclosures where heat and pressure must stay under control. Their compact motor design fits into tight spaces and makes them an ideal choice for challenging installations.

These fans use external rotor motors with aerofoil-designed metal blades to move air effectively. The motor lies within the airflow path, which allows space-saving and better cooling of the motor itself. Metal blades operate in extreme temperatures ranging from -40°C to +60°C.

These fans come in both single-phase (E-type) and three-phase (D-type) models. All models are available in suction (S) and blow (B) types and support 50 Hz frequency operation. Selected models also support 115 VAC input and operate efficiently from -40°C to +60°C.

Consider the following factors to select the right product for better performance:

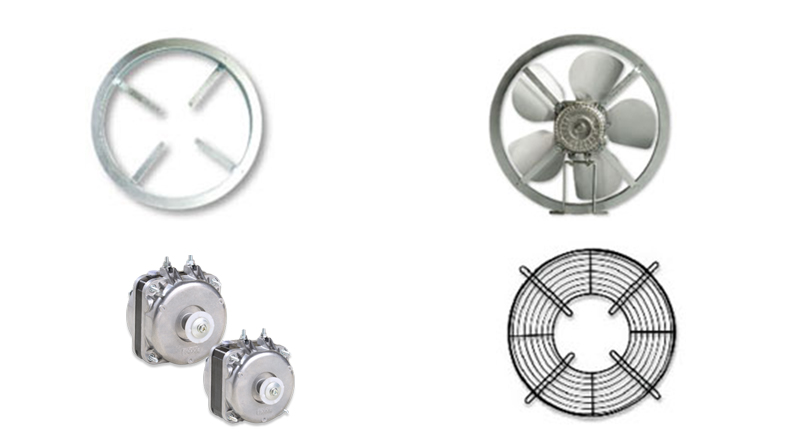

Shaded pole motors are compact AC motors ideal for low-power airflow applications. Available in two key types - Q Type and C Frame - these motors deliver dependable performance in appliances that operate under moderate conditions such as refrigeration units, display coolers, and medical equipment.

They use a simple coil and shaded ring system to create a rotating magnetic field. This design allows for low-cost and low-maintenance operation. They are often paired with plastic or aluminum impellers to circulate air in enclosed systems. Optimized for 50 Hz operation and offers long-lasting performance in humid or compact setups.

These motors are compact solutions built for simplicity, longevity, and low-cost operation. These motors function reliably in closed-loop systems where minimal airflow is needed over extended periods.

Consider the below factors to choose between Q and C Frame:

Backward curved fans also known as radial centrifugal fans, are designed to deliver reliable cooling in high-pressure environments. These fans feature specially engineered backward curved blades that offer superior airflow, dirt resistance, and high hydraulic efficiency which makes them an ideal choice for demanding industrial setups.

These fans use centrifugal force to push air outward and create strong airflow even in restricted or high-resistance systems. The blades curve away from the direction of rotation to reduce the chances of motor overload under varying pressure. These fans are built with external rotor motors and are optimized for both 50 Hz and 60 Hz frequencies.

These industrial-grade centrifugal fans are built to handle high-pressure and low-flow scenarios efficiently and have the following features:

When selecting, consider the air resistance in your system, space availability, voltage requirements, and other factors as mentioned below:

Cross flow blowers, also known as tangential blowers or crossflow fans, deliver consistent and widespread airflow across surfaces. These fans are ideal for applications requiring uniform air movement in systems with limited space. With low airspeed and quiet operation, they are well-suited for both industrial and commercial use.

They move air transversely across a cylindrical impeller. Unlike radial fans, airflow enters and exits on the same side to produce a broad and flat stream. The flow remains nearly two-dimensional which makes them highly efficient in systems needing steady airflow.

A compact and efficient fan offering low noise and steady airflow at low power comes with the following features:

These fans are optimal for systems that demand even air distribution with minimal turbulence. The below factors can help choose a suitable one:

Copyright © 2025 All Rights Reserved By KB Enterprises | Developed By Smart Stream Technologies