Industries operate better with smart automation and real-time insights

Industrial automation makes work easier with smart controls and real-time monitoring. It assists industries stay efficient by optimizing workflows, reducing inefficiency, and maintaining quality, keeping them future-ready.

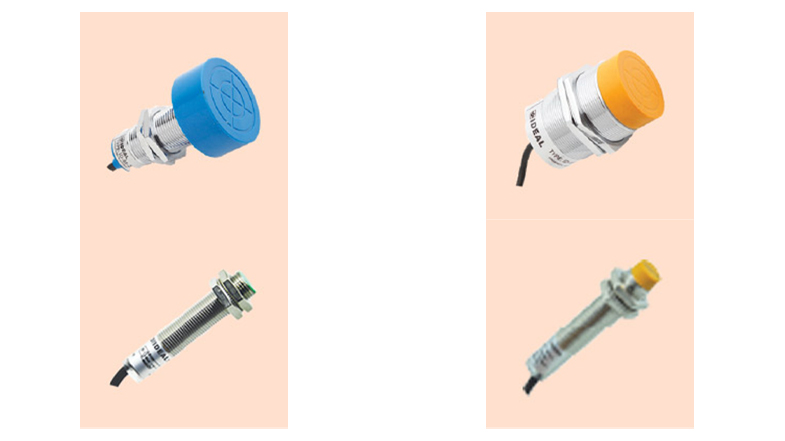

A proximity sensor is a component used in industrial automation and other applications to perform non-contact detections. It has no moving parts and can sense objects that come into contact with it without the need for touch.

They detect objects in their way and convert them into electrical signals. As soon as an object enters its range, it activates the ON signal.

Proximity sensors are useful for any applications to detect an object in a defined range and they are widely used in different environments such as:

Selecting the right proximity sensor depends on factors like the type of object being detected, environmental conditions, and the required sensing range. The four major types include capacitive, ultrasonic, inductive, and magnetic which come with different specifications and usage. Here’s a quick guide to help you decide:

A switched-mode power supply (SMPS) is a high-efficiency power conversion system that rapidly switches on and off at high frequencies. By using inductors and capacitors to store and release energy, it will maintain a steady power output even when the switch is off. This makes it a reliable and energy-saving solution for modern electronics.

SMPS uses high-frequency switching devices to convert AC to DC or vice versa. The process includes rectification, filtering, and pulse-width modulation (PWM) control to minimize energy loss and provide stable output voltage.

These power solutions are essential for maintaining stable electrical performance in:

A Solid-State Relay (SSR) is a high-performance electronic switch that replaces mechanical relays with semiconductor technology. It operates silently, switches instantly, and lasts significantly longer, making it perfect for precision-driven applications.

/Main Image/SOLID STATE RELAY.jpg)

When a small control voltage is applied, the SSR rapidly switches power to the load without moving parts for an uninterrupted operation. Whether for industrial automation, temperature control, or sensitive electronics, SSRs deliver efficiency, durability, and superior performance.

SSRs offer reliable, contactless switching with the panel, DIN rail, and PCB mounting options. They support up to 125A at 480VAC (hockey pack series) and 200VDC for DC loads. PCB-mounted versions handle up to 25A with built-in heat sinks. Features include LED status indicators, UL certification (CE/UKCA), and I/O modules for flexibility. They are used in:

SSRs provide efficient, maintenance-free operation for demanding environments.

/solid-state relay -1.png)

/solid-state relay - 2.png)

/solid state relay 3.png)

/solid-state relay 4.png)

/solid state relay 5.png)

A Micro & Limit Switch is a small but powerful device used for precise control in machines and automation. Limit Switches are built to withstand tough conditions like dust, water, and oil resulting in a perfect fit for industrial use. They come in different types, such as horizontal, vertical, and multiple-limit switches.

Micro and limit switches play a key role in industrial automation by detecting movement and controlling circuits. When a machine part applies force, the switch snaps open or closed in order to trigger an action. This guarantees accuracy, reliability, and smooth performance. Once the force is gone, the switch resets and is ready for the next cycle.

Micro & Limit switches are stable enough to endure numerous cycles without failure. Their versatility allows them to be used in various applications, from industrial machines to household appliances. They offer accurate detection of environmental changes for a smooth operation. Their durability withstands extreme conditions like temperature fluctuations and vibrations. Despite these advantages, micro & limit switches remain cost-effective and remain an economical choice for many industries.

Micro & Limit switches come in different specifications used across various industries. For industrial automation, ID-81 SERIES, IDCA SERIES, PRE-WIRE COMPACT, and IDSA SERIES provide decent switching. IDHL SERIES, THERMO PLASTIC, ID-J & ID-3SE3 SERIES, and ID-Z-15 are built for tough conditions. Compact options like D4MC, ID-61 SERIES, "V" TYPE & MINIATURE, and DOOR SWITCH work well in small spaces.

Blinking light multi-layer indicators, commonly known as tower lights or signal beacons, provide visual and audio alerts in industrial environments. These lights help to monitor the machine status, safety conditions, and workflow efficiency with multiple colored layers to indicate different statuses.

These lights function by emitting steady, flashing, or rotating signals, often combined with siren or buzzer sounds for better visibility and awareness. The different types include bulb-type blinking lights and tower lights that use incandescent or halogen bulbs, LED blinking lights and tower lights that are energy-efficient and bright, solar blinking lights for outdoor use and sirens with buzzers that provide audible alerts.

These lights are used in manufacturing plants to indicate machine operation, faults, or maintenance needs. Warehouses and logistics facilities use them to guide traffic flow and alert forklift operators. In construction and road safety, they serve as warning signals for hazardous zones. Public spaces and airports use them for emergency signaling and traffic control, while automation systems rely on them for real-time process status updates.

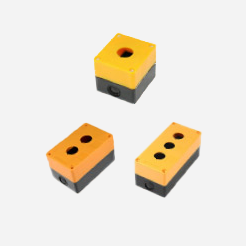

22.5MM signaling industrial control devices provide visual and manual control for machinery to offer a smooth and safe operation. Designed for easy panel integration, and they include push buttons, pilot lights, selector switches, and emergency stops.

When activated, these devices send electrical signals to control systems, triggering specific actions like machine start/stop, emergency shutdowns, or status indication. LED lights give instant visual signals, and their tough design makes them long-lasting in industrial settings.

22.5MM signaling control devices provide efficient operation and reliable performance in industrial settings and the below features justify it.

Selecting the right device depends on application needs, including voltage, durability, and mounting type for optimal performance.

A 16MM push button switch is a compact yet powerful electromechanical device designed to control electrical circuits with ease. They are widely used across industries and offer consistent functionality in a space-saving design. The 16MM size refers to its diameter and this remains as an ideal choice for installations where efficiency and compactness matter.

When pressed, the button either closes or opens the circuit, depending on its design. Momentary switches activate the circuit only while being pressed, returning to their original state when released. Latching switches, on the other hand, remain in the on or off position until pressed again, making them ideal for applications requiring a maintained operation. These switches ensure reliable control with a simple yet effective mechanism.

16MM push-button switches are quite famous and used in massive industries as well as household electronics. They play various roles like serving as an emergency stop button in industries or reset buttons in household appliances.

The following factors need to be considered before purchasing a 16MM push button switch for the best results.

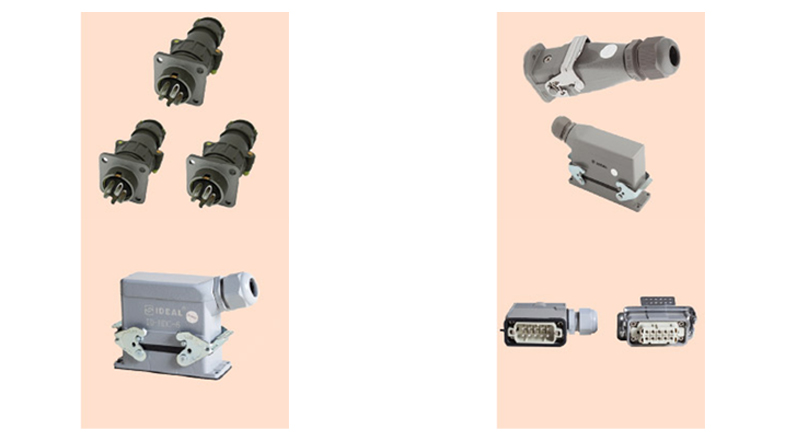

Heavy-duty connectors (HDCs) are industrial-grade rectangular connectors designed to transmit power, signals, and data in demanding environments. Built with sturdy materials, these connectors withstand mechanical stress, dust, moisture, and extreme conditions, making them essential for automation, robotics, and machinery.

HDCs operate by securely linking electrical circuits through a combination of contact systems, inserts, and protective housings. Their modular construction allows customization, integrating multiple connection types in a single unit. Designed for quick assembly and secure locking, they enable seamless connectivity while protecting electrical systems from external hazards.

Heavy-duty connectors are widely utilized across industries requiring durable and high-performance electrical connections. This includes manufacturing & assembly lines, power & energy, transportation & railways, aerospace & defense, and oil & gas.

HDCs are engineered for tough environments to offer superior connectivity with strong housings, secure locking mechanisms, and multiple termination options. They support high voltage, current, and signal applications to provide stable performance across various industrial settings.

Selecting the appropriate HDC depends on the application, environmental factors, and required performance specifications. Understanding the operational requirements helps in choosing the best connector for long-term efficiency and safety.

Cord end terminals are essential components in industrial automation which are designed to improve wire connections and electrical functions. These small, crimped metal sleeves, typically made of tinned copper, are fitted over the stripped ends of stranded wires. They ensure a secure, durable connection when inserted into terminal blocks, connectors, or screw terminals to prevent wire fraying and reduce the risk of electrical faults.

End cord terminals function by consolidating wire strands into a single, unified unit. The terminal is crimped onto the stripped wire using a specialized crimping tool, which compresses the metal sleeve to create a firm electrical connection. This process enhances conductivity, minimizes resistance, and protects wires from mechanical stress for long-term reliability in demanding industrial environments.

Cord-end terminals come in different types and configurations to suit various applications. Some key features include:

Selecting the appropriate cord-end terminal depends on several factors:

Contactors and bimetal relays are essential in industrial power management, controlling circuits, and preventing equipment damage from overloads. Contactors act as high-power switches, while bimetal relays detect excess current and disconnect circuits to avoid overheating.

Contactors use an electromagnetic coil to open or close circuits which is commonly found in motors and lighting systems. Bimetal relays rely on two metal strips that expand at different rates when heated to trigger a disconnect mechanism in case of overload.

Selecting the appropriate component depends on several factors such as:

For optimal performance, follow these best practices:

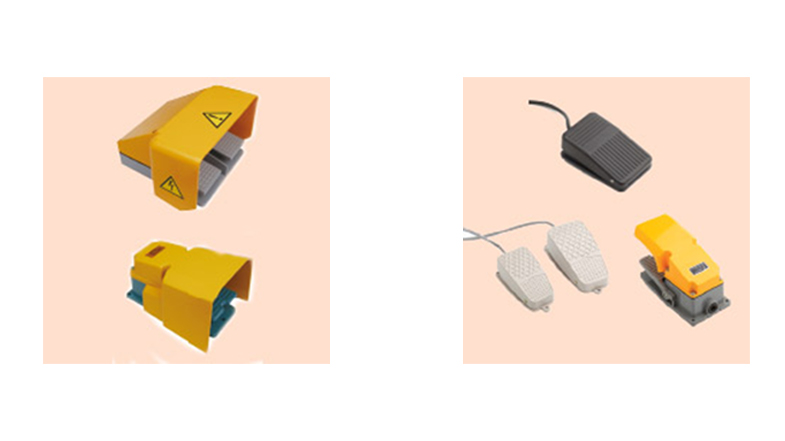

Foot switches are industrial control devices that let operators start or stop machinery with their feet, keeping hands free for other tasks. These switches improve productivity and workplace safety by offering hands-free control in demanding environments.

A foot switch activates when pressed to complete an electrical circuit to power a machine. Some models work momentarily, engaging only while pressed, while others maintain their state until pressed again, allowing for continuous operation without constant foot pressure.

Foot switches are essential in industries requiring hands-free machine control. Some of the applications include industrial machinery, medical equipment, textile & printing, automotive industry, metalworking.

Designed for various industrial applications, foot switches offer key features such as:

Consider these factors when selecting a foot switch for your application:

Crane pendants are handheld push-button stations used to operate EOT cranes to offer smooth and effective control over crane movements. These controllers come with waterproof emergency stop switches and various configurations, including dual-speed options for better handling.

Crane pendants enable operators to manage hoist movements in multiple directions like up, down, and along the X-Y axes for effective material handling. The push buttons trigger specific crane functions, improving precision and safety.

These control devices are essential in industries where accurate and efficient movement of machinery and loads is required, including manufacturing, construction, warehousing & logistics, shipyards, automotive industry, material handling equipment, and much more.

Built for durability and efficiency, crane pendants offer:

Choosing the right control device depends on various factors, including:

A water float switch is an automatic ON/OFF sensor that detects liquid level changes and activates electrical devices like motor pumps, solenoids, lamps, or relays. It optimizes fluid management by responding to rising or falling water levels.

As liquid levels fluctuate, the float sensor moves accordingly, triggering an internal switch. This signal can start or stop pumps, prevent overflow, or maintain a steady fluid level in tanks and reservoirs.

Water float switches play a crucial role in industries that require automated liquid level control. They are commonly found in water treatment plants, agriculture and irrigation, industrial cooling systems, wastewater management facilities, and more.

Water float switches are designed for efficiency and durability to offer:

Choosing the right water float switch depends on several key factors:

An AC solenoid is an electromagnetic actuator designed for rapid and efficient switching. It consists of a magnetizing coil and a plunger that moves in response to an electric current, making it essential for applications requiring fast and powerful actuation.

When an electrical current flows through the coil, it generates a magnetic field that pulls the plunger into a closed position. The force increases as the gap closes, enabling strong actuation. Once power is removed, a spring typically returns the plunger to its original position, resetting the system for the next cycle.

AC solenoids are widely used in industries that demand accurate and high-speed actuation. In energy technology, they facilitate efficient switching operations. Safety engineering applications rely on them for controlled locking and release mechanisms. Machine-building industries use them for automated movements, while switchgear construction benefits from their ability to handle high switching power with minimal delay.

AC solenoids are known for their efficiency and long-lasting performance which offers:

Selecting the right AC solenoid requires considering key factors:

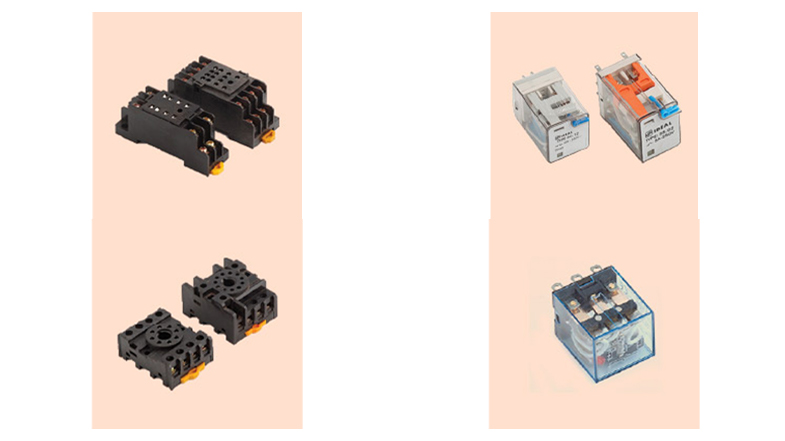

Relays are electrically operated switches used to control circuits, while relay bases provide secure mounting and connectivity for relays. Together, they form an essential part of industrial automation systems to enable effective and safe electrical control.

Relays use an electromagnetic coil to open or close circuits and allow remote control of electrical loads. When the coil is powered it creates a magnetic field that moves internal contacts to complete or break the circuit. Relay bases connect relays to electrical systems and makes sure the connections are secured and offers easy replacement.

Relays and bases are widely used across various industries requiring accurate electrical control. They are integral to automation systems, motor control centers, and industrial machinery. In energy distribution, relays provide safe circuit switching, while in manufacturing, they enable efficient control of motors, heaters, and lighting systems.

Relays and bases have multiple features and play a vital role in industrial automation. Some of them are listed below:

The following factors can help to choose the appropriate relays & bases that best suit your automation needs:

Cable glands are essential components used to seal and protect electrical cables as they enter enclosures or equipment. Nylon and metric cable glands provide effective strain relief while safeguarding connections against dust, moisture, and mechanical stress. They are available in PG and metric thread types, suitable for diverse industrial needs.

Cable glands secure cables by gripping them firmly and providing an airtight seal. When tightened, the gland compresses around the cable to prevent the movement and minimize the risk of environmental damage. These glands help keep enclosures sealed and protected in harsh environments.

Nylon and metric cable glands are widely utilized in automation, power distribution, and industrial manufacturing. They are essential in electrical panels, control cabinets, and outdoor installations where cable protection is crucial. Industries such as automotive, energy, telecommunications, and marine depend on them to maintain secure and organized wiring systems.

Nylon & metric cable gland are crafted for long-lasting performance and it offers:

The following should be the key considerations in choosing the right cable gland:

Porcelain fuses and fuse holders play a vital part in safeguarding electrical circuits from overcurrent damage. Crafted from high-quality porcelain, these components offer excellent thermal resistance and long-lasting durability and make them ideal for industrial applications. Fuse holders keep fuses secure which allows easy installation and quick replacements.

Porcelain fuses break the electrical circuit when excessive current flows and prevents equipment damage and lower the risk of electrical fires. The fuse element melts under overload conditions to immediately cut off power. Fuse holders keep the fuse firmly in place that makes the access easier for maintenance.

Porcelain fuses and fuse holders ensure safe operation in electrical systems. They are built with high-quality porcelain to offer excellent durability and insulation.

Porcelain fuse & fuse holder are designed for industrial-grade protection and some of its major features include:

The following factors need to be evaluated while selecting the right porcelain fuse & fuse holder:

Timers and meters are essential components in industrial automation which are used to monitor, measure, and control processes with accuracy. Timers regulate the duration of operations, while meters track electrical parameters like voltage, current, and frequency. These devices contribute to process efficiency, system protection, and energy management.

Timers function by initiating or halting operations after a preset delay, automating machinery sequences and process cycles. They operate in various modes, such as on-delay, off-delay, and cyclic timing. Meters continuously measure and display critical electrical values, helping operators monitor system performance in real-time.

The technical specifications of Timers & Meters vary according to the choice of product. A general overview is given below:

Choosing the right timer and meter requires analyzing several key factors:

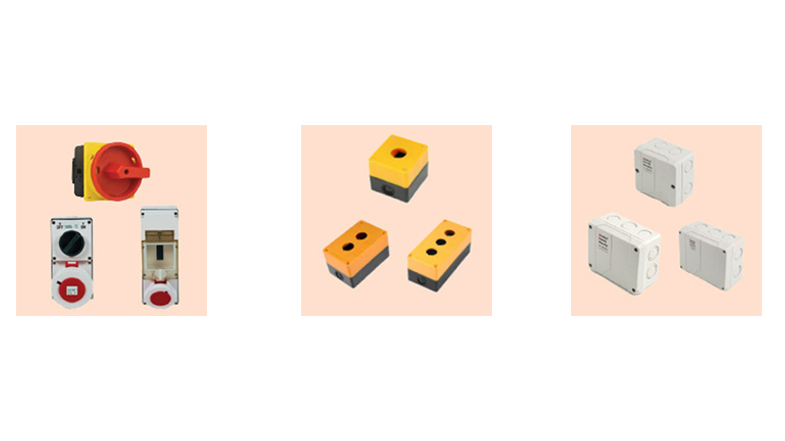

Industrial enclosures protect electrical and automation components by shielding them from dust, moisture, and mechanical impact for maximum durability. They improve safety, maintain organized wiring, and restrict unauthorized access to critical equipment.

Enclosures shield electrical components from external elements and mechanical damage. They are constructed from durable materials like thermoplastic, PVC, or metal to provide insulation, corrosion resistance, and secure mounting for control equipment. These enclosures also integrate ventilation and security features to sustain performance in demanding conditions.

Enclosures are inevitable in harsh industrial environments and the key features mentioned below justifies it:

Industrial enclosures come in various types to suit specific applications. Control boxes serve as enclosures for electrical controls and automation circuits in industrial setups. Thermoplastic boxes offer lightweight and corrosion-resistant protection that makes them ideal for outdoor and high-moisture environments. Isolators feature integrated switch disconnects for safe circuit isolation and maintenance operations. Empty PVC enclosures provide flexibility and durability, accommodating a range of electrical components and configurations.

Selecting the best industrial enclosure involves considering several factors such as:

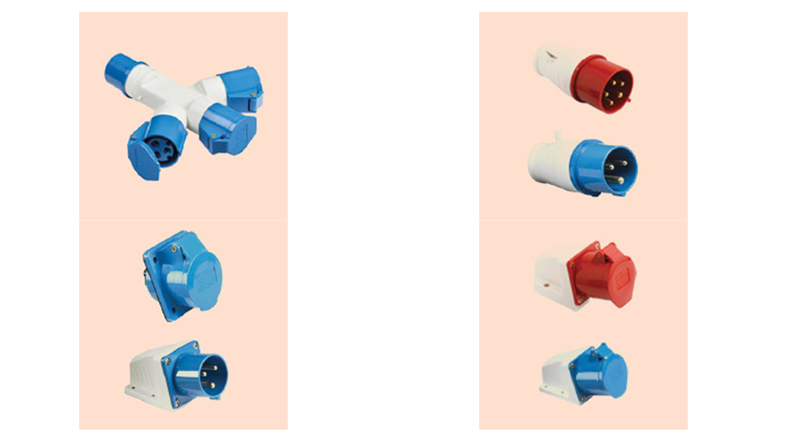

Industrial plugs and sockets are built to handle high voltages and currents which is essential for various demanding environments. They resist dust, moisture, corrosion, and physical impact to provide safe and efficient power distribution.

These connectors ensure safe electrical connections in industrial environments. They have strong casings, locking features, and quality materials to prevent loose connections and hazards. Various types are available for single-phase and three-phase systems.

Industrial plugs and sockets are manufactured to increase the industries’ efficiency and its key features include:

Industrial plugs and sockets are available in different types, and the major ones include 3-pin plugs and sockets, 5-pin plugs and sockets, interlocked sockets, and AC distribution boxes with sockets.

To select the right plug and socket, the following factors need to be considered:

Copyright © 2025 All Rights Reserved By KB Enterprises | Developed By Smart Stream Technologies