Reducing excessive currents and voltages to values that can be safely and precisely monitored.

Current transformers (CTs) reduce high currents to safe levels for accurate measurement and protection, while voltage transformers (VTs) do the same for voltage. They work together to maintain safe, effective energy distribution, fault detection, and power monitoring.

Current transformers (CTs) are essential electrical instruments designed to measure and monitor alternating current (AC) in power systems. By producing a proportional current in their secondary winding, they enable accurate metering, protection, and isolation from high-voltage circuits.

Current transformers function by transforming high primary currents into manageable secondary currents for safe and precise measurement. The design minimizes power loss, enhances insulation, and provides voltage isolation between the conductor and measuring circuitry.

A variety of current transformers are available to suit different operational needs.

The following factors need to be considered while selecting the right transformer to suit various industrial needs.

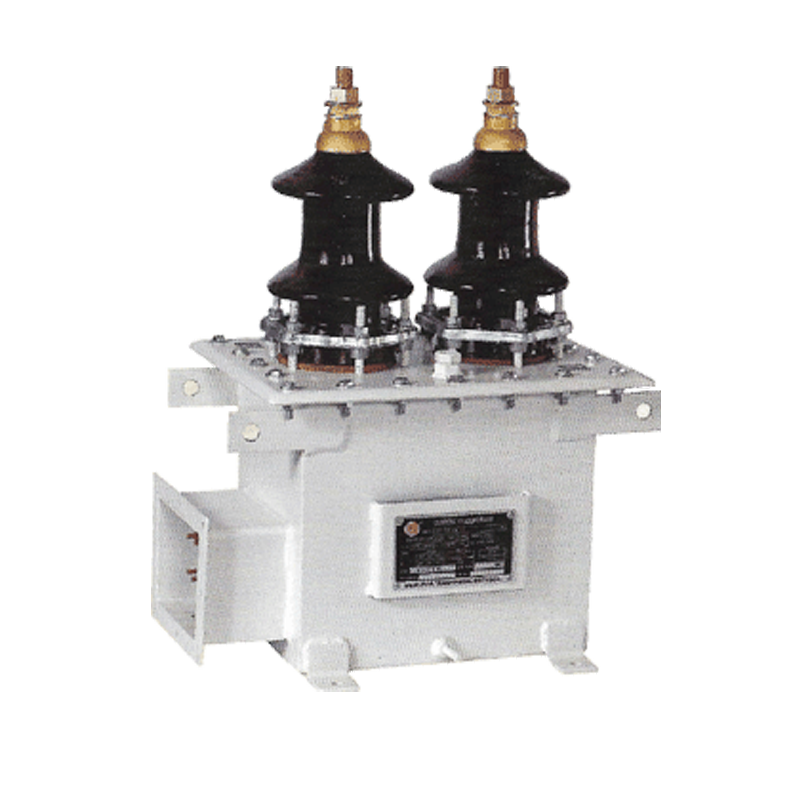

Potential transformers (PTs), also called voltage transformers, reduce high voltage to safe, measurable levels for metering and protection. They ensure accurate voltage measurement while keeping measuring instruments safely isolated from high-voltage circuits.

Potential transformers work by reducing the high primary voltage to a lower, standardized secondary voltage. This allows for the safe measurement of electrical parameters and protection against overvoltage situations. Depending on the application, PTs can be configured in various designs, including indoor, outdoor, and medium-voltage versions.

The diverse range of potential transformers offers various voltage ratings, insulation classes, and mounting options in order to suit different industrial applications.

Low-tension (LT) Current Transformers (CTs) lower high currents to safe levels for measurement and protection. They help monitor current flow in low-voltage systems while keeping measuring instruments safely separated from high-current circuits.

LT Current Transformers function by proportionally reducing the primary current to a standardized secondary current for safe measurement and control. These transformers are available in various designs such as tape-insulated and epoxy resin-molded (dry type) configurations which suit a wide range of industrial and commercial applications.

Selecting the appropriate LT Current Transformer depends on various factors such as current rating, insulation type, and application requirements.

.png)

Copyright © 2025 All Rights Reserved By KB Enterprises | Developed By Smart Stream Technologies