Small components play a big role in ensuring efficiency, safety, and reliability.

Power and control systems are supported and improved by electrical accessories. They support uninterrupted service across industrial and commercial settings by assisting with connectivity, protection, organizing, and maintenance.

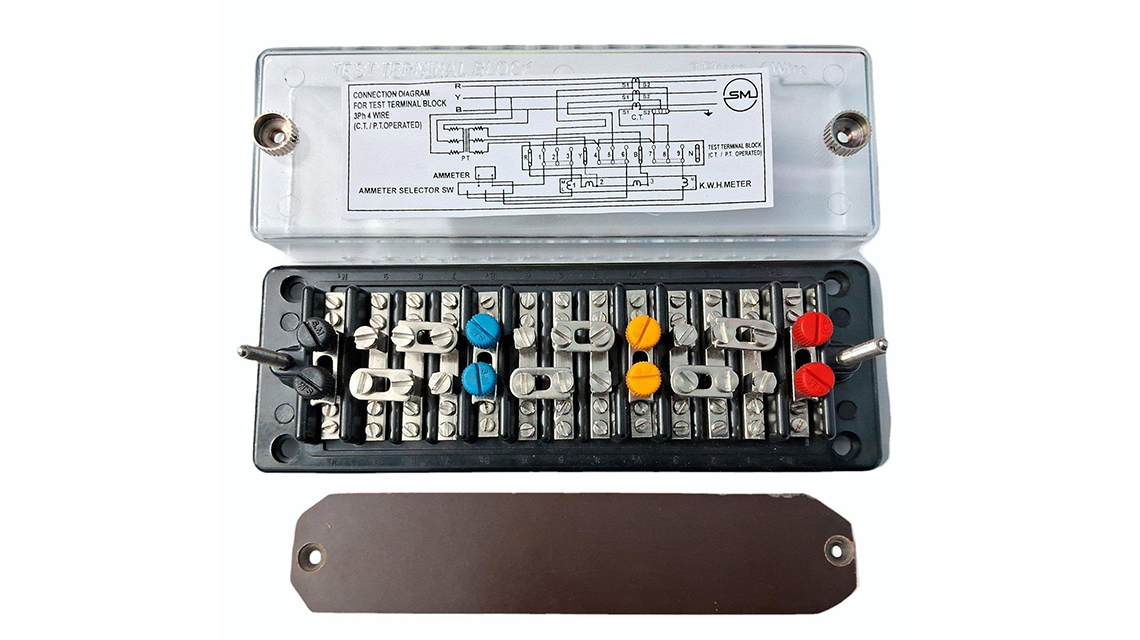

A useful method of testing electrical circuits without unplugging wiring is to use test terminal blocks. They are crucial in industrial and control panel systems because they enable speedy diagnostics, troubleshooting, and maintenance.

Because these terminal blocks have designated test locations, connecting measuring devices is simple. They maintain circuit integrity while providing safe and precise readings because to their sturdy insulation and clamping.

Test terminal blocks support efficient electrical testing in:

Selecting the right type depends on:

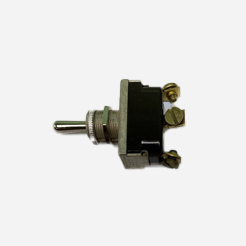

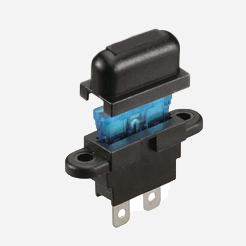

Toggle switches offer a straightforward way to control electrical circuits with a quick flip. Known for their durability and ease of use, they are widely used in industrial, automotive, and electrical applications where reliable switching is essential.

To open or close the circuit, these switches use a lever that moves between fixed positions. They can tolerate varying voltage and current levels depending on the application and come in single-pole and multi-pole variants.

Toggle switches are used across industries for quick and reliable circuit control. Their versatility makes them ideal for:

Picking the right switch depends on your circuit needs and environment. Key factors include:

By avoiding rust, lowering friction, and maintaining clean surfaces, maintenance, and protection sprays assist mechanical and electrical components last longer. They are extensively utilized in everyday applications, workshops, and industries.

These sprays penetrate surfaces, displace moisture, and create a protective barrier against corrosion, dust, and wear. Some formulas also provide lubrication, reducing friction in moving parts for better efficiency.

Maintenance sprays are essential for keeping equipment in top condition across various fields, including:

The right spray depends on what you need to protect and maintain. Key factors to consider:

Capillary thermostats sense changes and initiate the required adjustments to assist in control of the temperature in heating and cooling systems. When exact temperature control is required, they are frequently utilized in both domestic and commercial settings.

These thermostats sense temperature changes using a capillary tube filled with fluid. The fluid expands or contracts when the temperature reaches a certain point, turning on a mechanical switch that regulates the heating or cooling component.

Capillary thermostats play a crucial role in maintaining safe and efficient operations across various applications:

Selecting the right thermostat depends on the application and required temperature range. Key factors to consider:

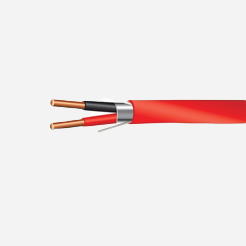

Across a range of commercial and industrial uses, these cables carry signals and electricity. Their robust and efficient design facilitates even power distribution and accurate control in automated systems, equipment, and panels.

Between equipment, these wires transmit control signals or electrical power. Their adaptability makes routing in confined locations simple, and their robust insulation guards against environmental influences, mechanical stress, and electrical interference.

From heavy-duty machinery to delicate control circuits, these cables are essential in:

Picking the right cable depends on voltage, flexibility, and environmental conditions. Key factors include:

Hour meters and impulse counters assist in monitoring equipment run time and counting electrical pulses, providing critical data for maintenance and performance tracking. They are widely used to keep operations organized and efficient.

Hour Meters record the total operational time of machines by tracking power-on durations. They help schedule maintenance and assess machine efficiency.

Impulse Countersregister electrical pulses or mechanical actions, making them useful for counting cycles, operations, or production output.

These monitoring tools play a key role in various industries, including:

Selecting the right device depends on usage type and installation needs. Key factors include:

Non-adhesive tapes don't leave sticky residues and are used for protection, insulation, and bundling. They are perfect for electrical work and cable management because of their durability and flexibility.

Non-adhesive tapes keep items together via friction, wrapping tension, or unique characteristics, in contrast to ordinary tapes. While some give reinforcement or insulation without adhering to surfaces, others, like self-fusing silicone tapes, attach to themselves.

These tapes are widely used in various industries for different purposes, including:

The right tape depends on its intended application. Key factors to consider:

.png)

Spiral bands keep cables flexible for mobility while organizing and protecting them. They make it simple to bundle several wires, which clears up clutter and guards against damage in any arrangement.

By forming a spiral pattern around cables, these bands enable users to add or remove wires without having to cut or rewrap everything. They can expand or compress to accommodate varying bundle sizes, and their open design keeps airflow constant, reducing overheating.

Spiral bands are widely used in various settings to manage and protect wiring, including:

Selecting the right band depends on cable size, material, and environment. Key factors to consider:

To protect electrical circuits from overloads and short circuits, porcelain fuse carriers offer fuses with a robust and heat-resistant casing. They are perfect for high-voltage, industrial applications where safety is a top concern because of their insulating qualities.

To facilitate simple installation and replacement when necessary, these carriers hold and secure fuses in place. Constructed from premium porcelain, they resist electrical stress and high temperatures, avoiding malfunctions in difficult settings.

Porcelain fuse carriers are a key component in various electrical systems, including:

Selecting the right carrier depends on fuse type, voltage rating, and installation needs. Key factors to consider:

Electrical connections in high-demand settings are made safe and long-lasting by industrial plugs and sockets. They provide defense against harsh weather, moisture, and dust, which makes them perfect for industrial use.

Power sources and equipment are electrically connected firmly by these plugs and sockets. They ensure reliable operation by reducing power loss and preventing unintentional disconnections thanks to their sturdy enclosures and precise contact points.

Industrial plugs and sockets are essential in various sectors that require stable and protected power connections, including:

The right choice depends on voltage, current rating, and environmental factors. Key considerations include:

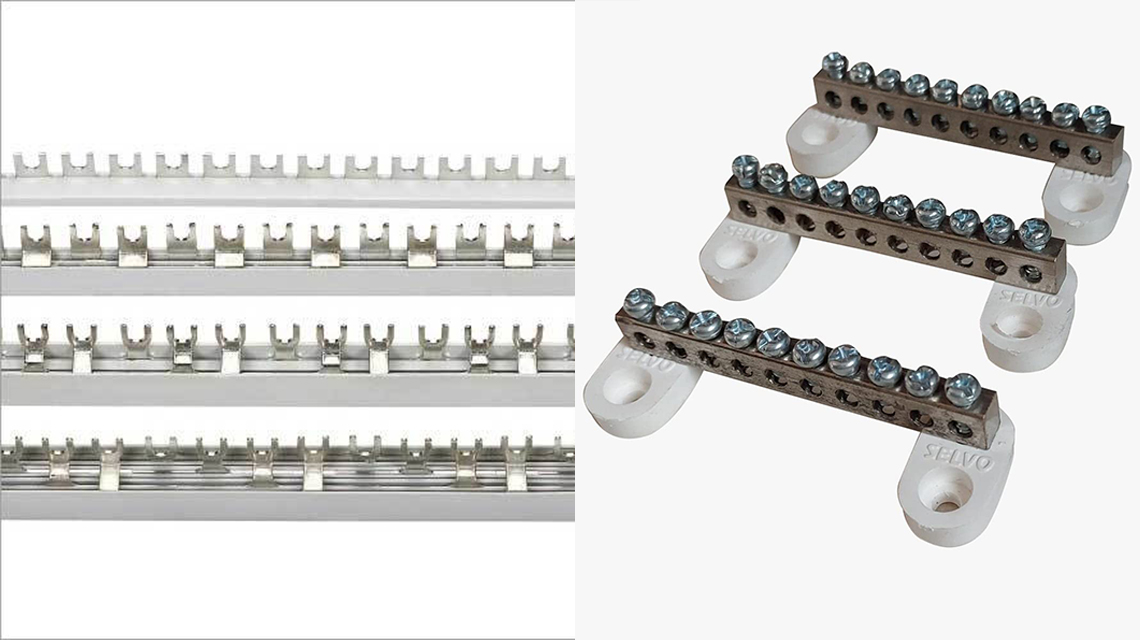

Neutral bars and MCB shorting handles electrical distribution by providing a common point for neutral connections and enabling quick interlinking of miniature circuit breakers. They improve wiring efficiency and reduce clutter in distribution boards.

Neutral Bars provide a shared connection point for neutral wires in electrical panels, ensuring proper grounding and circuit stability.

MCB Shorting Linksconnect multiple breakers, allowing simultaneous switching and reducing the need for excess wiring. They simplify electrical layouts and enhance system safety.

These components are widely used in electrical panels and power distribution systems across:

Selecting the right type depends on panel requirements, wiring capacity, and safety standards. Key considerations include:

Electrical enclosures are safeguarded by panel locks, PVC/rubber beading, and gaskets, which offer safe locking mechanisms, protective sealing, and vibration, moisture, and dust resistance.

Panel Locks keep enclosures tightly secured, preventing unauthorized access and ensuring internal components stay protected.

PVC / Rubber Beadingacts as a cushion, sealing panel doors and edges against environmental factors like dust and water.

Gasketscreate a tight barrier, preventing leaks and insulating against external contaminants, heat, and pressure variations.

These components play a key role in maintaining electrical enclosures across various industries, including:

Selecting the right sealing and locking components depends on enclosure type, environmental exposure, and security needs. Key factors include:

Electrical wires are protected from mechanical wear and tear by polyamide hoses and glands, which offer robust, flexible protection. These parts are frequently found in sectors where cables must be arranged, fastened, and shielded from adverse environments.

Polyamide Hoses act as a protective conduit, guiding cables through industrial setups while preventing damage from abrasion, chemicals, and temperature fluctuations.

Cable Glands secure cables in place, offering strain relief and sealing entry points to keep out dust, water, and other contaminants.

These protective solutions are essential in various industries for cable management and protection, including:

Selecting the right combination depends on cable type, environmental exposure, and installation requirements. Key factors include:

Door hinges and knobs are essential for both movement and security. Hinges provide stability and controlled motion, while door knobs offer a reliable and convenient way to open and secure doors—whether in industrial setups, machinery enclosures, or everyday spaces.

Door Hinges connect the door to the frame, allowing it to pivot open and close with controlled movement. Different hinge types cater to varying load capacities and usage conditions.

Door Knobs act as the primary interface for opening and securing doors, available in various locking mechanisms for different security needs.

These components are found in a wide range of applications where secure and reliable door operation is essential:

Selecting the right hardware depends on door type, weight, and security needs. Key factors include:

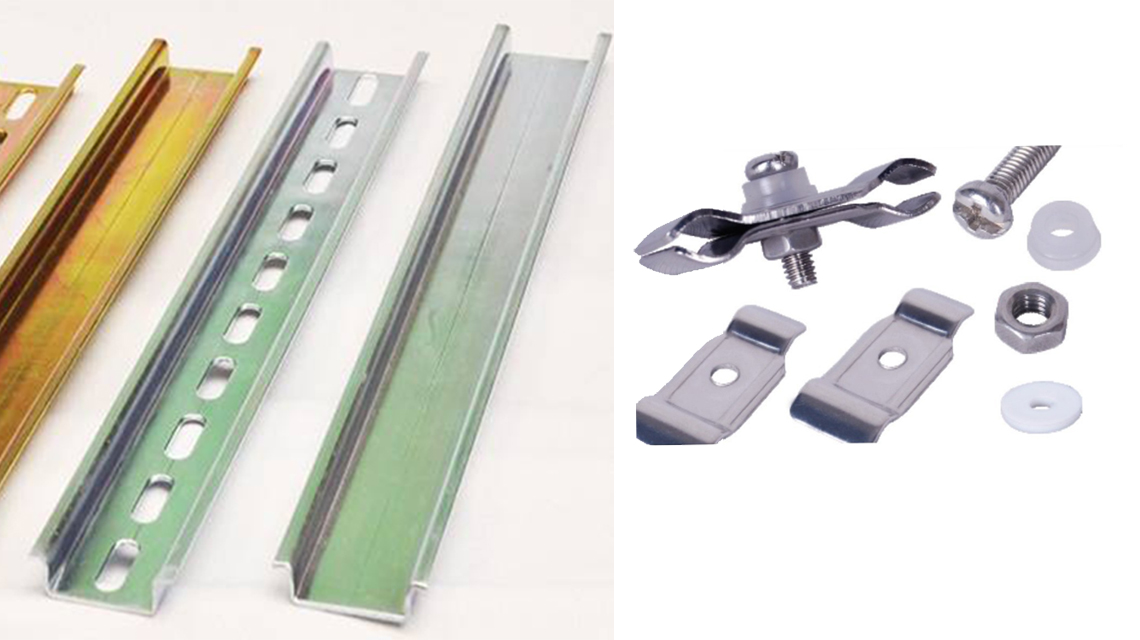

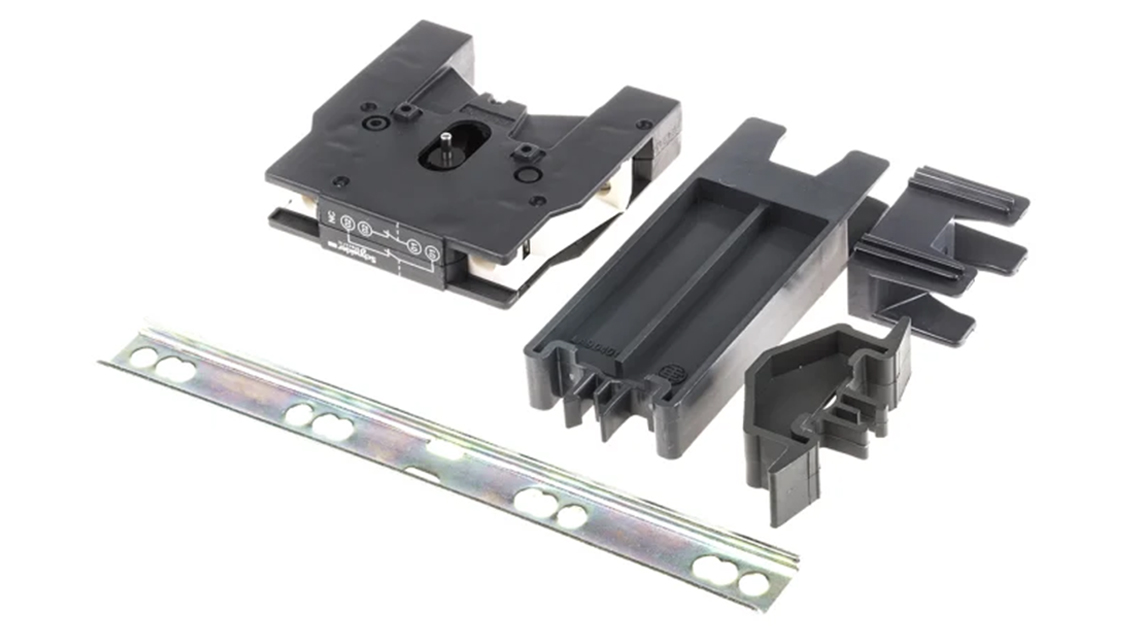

An orderly method of mounting electrical devices inside control panels and enclosures is provided by DIN rail and clip-on channels. They are appropriate for installing electrical systems since they improve wiring, increase accessibility, and hold the components in place.

DIN Rail Channels offer a standardized mounting system where circuit breakers, relays, and other control devices can be easily installed and adjusted.

Clip-On Channels provide a flexible and quick solution for securing wiring and components without additional fasteners.

These channels are widely used in electrical and automation setups, including:

Selecting the right channel depends on mounting needs and environmental factors. Key considerations include:

It is simpler to recognize functions and operate machinery when controls, switches, and equipment are labeled with legend plates and panel stickers. They increase industrial clarity, lowering the possibility of mistakes and promoting safety.

Legend Plates are durable engraved or printed labels fitted around switches, push buttons, and control panel components to indicate their function.

Panel Stickers provide adhesive-based labeling solutions for marking equipment, warning signs, and operational instructions.

These identification solutions are essential in environments where clear labeling is critical, including:

The right labeling solution depends on durability needs and environmental conditions. Key factors include:

For metalworking, electrical, and electronic applications, lead alloys and soldering flux provide strong, conductive junctions. While flux cleans and prepares surfaces for improved adhesion and conductivity, lead alloys offer a robust and stable soldering medium.

Lead Alloy serves as the core soldering material, melting at a controlled temperature to form solid, long-lasting joints.

Soldering Flux removes oxidation, prevents contamination, and improves the flow of molten solder for cleaner and more effective bonding.

These materials are essential in industries that require precise and durable soldering, including:

Selecting the right combination depends on application needs and environmental factors. Key considerations include:

.rar.png)

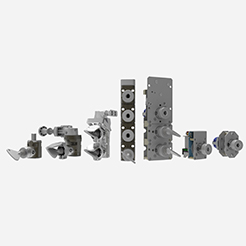

Deepak Mechanical Interlocks add an extra layer of security to electrical systems by preventing unintended operations. They are used in industries where controlled switching is mandatory to avoid hazards and equipment damage.

Mechanical interlocks function as a locking mechanism that restricts the operation of one switch unless specific conditions are met. By physically blocking movement, they help in safe load transfer, preventing simultaneous engagement of multiple power sources.

These interlocks are critical in environments requiring structured power control and operational safety, such as:

Selecting the right interlock depends on the application and safety requirements. Key factors to consider:

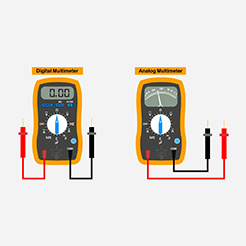

Among the instruments used to diagnose and troubleshoot electrical circuits are multimeters, clamp meters, and continuity testers. These tools help experts work safely and precisely, measuring everything from voltage and current to continuity and resistance.

Multimeters measure voltage, current, resistance, and other electrical parameters, making them versatile for testing and fault detection.

Clamp Meters allow non-contact current measurement by clamping around a conductor, making them ideal for high-power applications.

Continuity Testers check for complete circuits, helping identify breaks or faults in wiring and connections.

These testing tools are widely used in various industries, including:

Picking the right tool depends on your testing needs and the type of electrical work involved. Key factors to consider:

Wire strippers and crimping tools are used for electrical connections and effective cable preparation. These tools are essential for handling repairs, wiring industrial equipment, and assembling control panels.

Crimping Tools compress connectors onto wires, forming a firm electrical bond without the need for soldering. Available in manual, ratchet, and hydraulic variants, they are suited for different wire sizes and applications.

Wire Strippers By removing insulation without causing harm to the conductor, guarantee precise and hygienic cable preparation for terminal connections, soldering, or crimping.

These tools are widely used in:

Selecting the right crimping or stripping tool depends on wire type, connector compatibility, and usage frequency. Key factors to consider:

Strong pressure is produced by hydraulic crimping equipment to ensure dependable connections in high-power electrical systems. These tools offer accuracy with little effort, whether working with industrial wire, thick cables, or heavy-duty lugs.

They create a strong electrical link by compressing cable lugs and connectors under hydraulic pressure. Having a greater crimping capacity and use less physical force than manual crimpers, which makes them perfect for demanding applications and large-diameter cables.

Hydraulic crimping tools are essential in:

Selecting the right tool depends on the cable size, application, and operational convenience. Key factors to consider:

By regulating voltage levels, maximizing energy use, and avoiding needless waste, Sunbim Energy Regulators control power consumption. They support industrial applications requiring precise energy regulation, lighting controls, and heating systems.

By altering voltage or current, these regulators help maintain steady performance and cut down on energy waste by controlling the power sent to electrical loads. To control energy flow and extend the life of the equipment, they employ burst firing or phase angle procedures.

Sunbim Energy Regulators play a key role in:

Selecting the right regulator depends on load type, power rating, and control features. Key factors to consider:

Copyright © 2025 All Rights Reserved By KB Enterprises | Developed By Smart Stream Technologies