Electrical systems that depend on smart protection, precise control, and quick fault response.

Switchgears monitor and manage electricity flow, providing real-time protection against faults, overloads, and short circuits. By automatically disconnecting faulty circuits and redistributing power, they minimize disruptions and improve the reliability of power networks.

Air Circuit Breakers (ACBs) are designed to protect electrical systems from overcurrent, short circuits, and other faults in low-voltage distribution networks. These breakers oversee operational safety, reliability, and efficiency and offer flexibility in various industrial, commercial, and infrastructure applications.

ACBs function by automatically interrupting excessive current flow during faults and prevents damage to electrical systems. They operate in the air as an arc-extinguishing medium, ensuring reliable circuit protection. Designed for high-power applications, ACBs provide enhanced safety, modularity, and longevity.

ACBs come up with two different types. One is OMEGA Air Circuit Breakers which are compact and reliable for high-power, low-voltage distribution (400A–6300A) and meet all safety standards. Another one is C-Power Air Circuit Breakers which protect electrical systems from faults, with a 100kA withstand capacity and easy maintenance. They also offer special designs for harsh environments. The other features include:

Consider the following factors before selecting the ideal ACB:

Moulded Case Circuit Breakers (MCCBs) protect electrical circuits from overloads, short circuits, and faults. With a durable design, high breaking capacity, and protection features, MCCBs enable efficient and safe power distribution in electrical systems.

MCCBs disconnect a circuit when abnormal current conditions are detected. They feature both thermal-magnetic and microprocessor-based protection mechanisms to provide operation across applications. With high fault-breaking capacities, MCCBs help maintain a safe and continuous power supply in various environments.

It offers four various models designed for different needs. The DZ range supports modern electrical installations with high fault-breaking capacities up to 200kA at 415V AC. The DN range is built for tropical conditions, featuring options for both AC and DC applications. The DY and DU series focus on compact design, flexibility, and compliance with international safety standards and offer breaking capacities from 10kA to 50kA. Each series includes multiple pole configurations for adaptability across industrial and commercial setups. Apart from the above, their other features include:

The following factors help to choose the right MCCB:

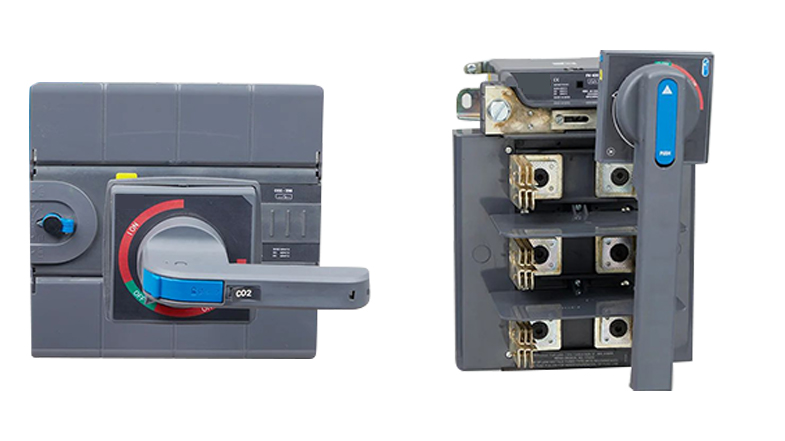

Switch Disconnectors and Switch Disconnector Fuses (SDFs) help for safer disconnection and isolation of electrical circuits in industrial and commercial applications. These switches are easy to install, use, and inspect. They provide secure switching solutions in demanding environments.

SDFs operate as primary isolation devices that safely disconnect electrical circuits under load conditions. They integrate protective features such as terminal shrouds, phase barriers, and high-ground clearances to prevent electrical hazards.

They are widely used in power distribution systems, motor control centers, industrial panels, and commercial electrical installations. They help improve system safety, ease maintenance and ensure effective power management.

SDFs are known to improve safety, efficiency, and durability. They help prevent arcs, provide strong insulation, and ensure reliable operation.

To find the right product, consider usage needs, safety measures, and installation factors. Important aspects include switching frequency, protective components, available space, and environmental suitability.

Contactors play a vital role in motor control, supply changeover, and capacitor switching applications. They are specifically designed for industrial and commercial setups, and support both single-phase and three-phase circuits.

Contactors control power flow by opening and closing contacts based on external signals. Their design minimizes power loss and supports smooth operation in varied conditions, from motor feeders to capacitor switching panels.

The range includes MCX (18A–900A AC-1) for auto-source transfer applications, MNX (9A–650A AC-3) for motor feeders, MO (9A–300A AC-3/3e) for machinery, MO0 control contactors for flexible logic construction, and MO C capacitor duty contactors for mitigating inrush currents in APFC panels. Some of their key features include mechanical interlock in MCX for safety, accessible terminals in MNX for easy maintenance, compact designs in MO to save space, surge suppression in MO0 for voltage spike protection, and damping resistors in MO C for capacitor switching efficiency. The other notable information is listed below:

Selection depends on application type (motor control, capacitor switching, or source transfer), current rating, contact configuration (2NO 2NC, auxiliary contacts), control voltage (AC or DC), and space/mounting needs. Based on the industrial need and with respect to the above factors, the right contactor can be chosen for effective usage.

Industrial starters support motor protection and control in diverse industrial settings. The MN range provides dependable solutions for stand-alone motors and offers a long-lasting performance in challenging conditions.

These starters manage motor operation by regulating power flow and guarding against electrical faults. They help prevent damage from issues like single phasing and overload conditions and extend the motor life.

Industrial starters ensure protection and easy operation with base plate mounting, IP54 protection, and flush-mounted push buttons. They offer single-phasing protection, flexible reset options, quick fault detection, and precise timing control in the MN FASD model. Their key features include:

Consider these crucial factors when selecting an industrial starter:

Motor protection circuit breakers help in preventing damage to motors by controlling electrical faults. It combines the functions of a moulded case circuit breaker and a thermal overload relay into a compact unit. This design allows for effective protection against short circuits and overload conditions while reducing installation space and wiring complexity.

It integrates overload relay functions within its small framework and regulates power flow to prevent electrical faults that can harm motors. The adjustable current range dial allows fine-tuning to match motor requirements. This helps in maintaining smooth operation and reduces downtime.

Motor protection circuit breakers are used in industries that require compact motor control solutions. They are suitable for small to medium motor loads and applications that demand high breaking capacity. These units help in maintaining efficiency while reducing panel size and wiring efforts.

The MOG MPCB is designed for various applications that require high breaking capacity and compact installation. It comes with essential features for safety and convenience such as:

Selecting the right motor protection circuit breaker depends on several factors:

Electronic motor protection relays help safeguard motors from electrical faults. They prevent failures, reduce downtime, and increase motor efficiency. These relays offer protection, control, and monitoring features to support different motor installations in industrial settings.

These relays monitor electrical parameters and protect against voltage fluctuations, overload, and earth faults. They provide real-time operational and diagnostic data to help prevent major failures. The built-in starter logic makes setup quick and reduces commissioning time.

These relays detect faults early to reduce downtime. Their compact design and pre-programmed logic simplify installation. The software suite allows easy configuration and diagnostics. Advanced features support complex logic building and a few technical aspects are mentioned below:

Consider the below-listed factors when selecting a relay:

Overload relays protect motors from excessive current, overheating, and single phasing. They work with various motor starter combinations and help prevent damage caused by overload conditions. Different types of overload relays offer protection suited to various applications.

Overload relays detect excessive current flow in motors. They trip the circuit if the current exceeds safe levels to prevent damage. Many models offer ambient temperature compensation and single-phasing protection. Some include auto and manual reset functions for flexible operation.

The OLR comes in 3 different variants with unique features that suit different industrial needs. This includes MN Thermal Overload Relays for MNX contactors with Trip Class 30 for long start applications, RTO Thermal Overload Relays for MO contactors with front-access buttons and visual indicators, and REO Electronic Overload Relays with ground fault protection, locked rotor detection, and trip indication via mechanical flag and LED flash. The other features include:

When selecting the relay, consider the following factors:

Miniature Circuit Breakers protect electrical circuits from short circuits and overloads. They prevent damage to wiring installations and reduce electrical hazards. MCBs come up with different types and cater to residential, commercial, and industrial needs.

MCBs detect abnormal current flow and trip the circuit to prevent damage. Unlike traditional fuse units, they can be reset and reused which makes them a cost-effective solution. Advanced features like true contact indication, trip-free mechanisms, and flexible termination options improve safety and convenience.

The EXORA range ensures a safe environment with low watt loss, reducing electricity consumption. AU Solutions protects against overload and short circuits with the lowest watt loss in the industry. The Tripper range is designed for residential safety, ensuring secure power distribution.

Consider the following factors to choose the right one that fits your needs:

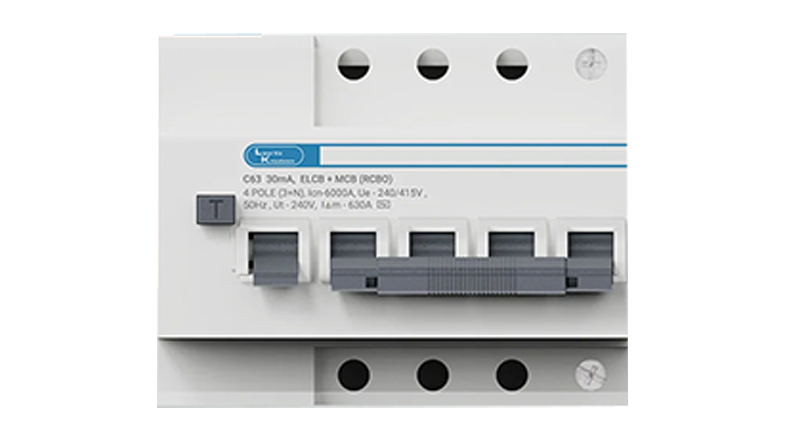

Residual Current Operated Circuit Breakers (RCBOs) provide essential protection by detecting and interrupting faults such as overloads, short circuits, and earth leakages. They prevent electrical hazards which makes them an ideal choice for a wide range of applications.

RCBOs constantly check the flow of electricity in circuits. If a problem occurs, they shut off the power to prevent shocks, fires, and damage. RCBOs are better than other regular breakers as they protect against overloads, short circuits, and earth leakages in one device.

They are used in homes, offices, and industrial setups where electrical safety is a priority. They protect appliances, wiring, and individuals from electrical risks by providing fast and efficient fault detection. The AU range of RCBOs includes advanced protection features for enhanced electrical safety such as:

In order to choose the appropriate product, the following factors must be analyzed:

Earth-Leakage Circuit Breakers (ELMCBs) provide comprehensive protection against electrical hazards by detecting faults and disconnecting power before damage occurs. They help to prevent electric shocks, reduce fire risks, and enhance overall safety in homes and workplaces.

It monitors electrical circuits for leakage currents, overloads, and short circuits. If a fault is detected, the breaker trips to cut off the power to prevent electrical hazards. By combining the functions of an Earth Leakage Circuit Breaker (ELCB) and a Miniature Circuit Breaker (MCB), ELMCBs offer a complete safety solution in a single device.

It will provide all-in-one protection against electrical hazards and prevent electrocution & fire risks to help maintain efficient power distribution.

Check out the below-listed factors that play a major role in helping to select the right product:

Residual Current Circuit Breakers (RCCBs) detect leakage currents and disconnect power to prevent electric shocks and fire hazards. They create a safe environment in homes and workplaces.

RCCBs track the movement of electrical current within a circuit. If they detect an imbalance caused by leakage, they immediately disconnect the power supply. This swift action helps prevent electrical hazards, and keep both the people and equipment safe.

They are operated in residential, commercial, and industrial settings to protect against earth leakage faults. They reduce risks from faulty appliances, damaged wiring, and unexpected current leaks.

With the following simple yet effective factors, one can easily determine the right product to suit various needs:

Modular Change Over switches transfer power sources without delay. They support power continuity in homes, businesses, and industries, keeping operations uninterrupted.

These switches manually shift electrical loads between two power sources. They provide a dependable way to maintain power flow and enable easy transitions between the main supply and backup power.

Modular Change Over switches function in commercial buildings, industrial setups, and homes. They maintain power availability and serve as an essential component for businesses and households. Some of their attributes include:

When picking the switch, consider the following factors:

Modular Contactors perform remote switches and automatic control of electrical devices in homes, commercial buildings, and industrial facilities. They help manage electrical loads, efficiently reduce power consumption, and improve safety by preventing electrical faults.

Modular Contactors function as electromechanical switches that operate electrical circuits from a remote location. When they receive a control signal they either complete or break the circuit between a power source and connected electrical equipment. This switching mechanism helps in automating operations and optimizing energy use in various applications.

These contactors provide effective control and automation for electrical circuits. They support a wide range of applications and enhance operational safety by minimizing risks related to electrical faults.

Selecting a suitable contactor requires evaluating key factors that affect performance and compatibility. A well-matched contactor contributes to safer and more efficient electrical operation.

Surge Protective Devices protect electrical and electronic equipment from sudden overvoltage spikes. These spikes occur due to lightning strikes or switching surges and may cause damage to sensitive circuits. The AU Solutions range of SPDs prevents such damage and enhances the safety of electrical systems.

SPDs detect sudden voltage increases and divert excess energy away from connected devices. When a surge occurs they respond instantly by channeling the extra voltage to the grounding system. This action prevents excessive voltage from reaching electrical equipment and reduces the risk of system failures.

These devices provide effective surge protection and help maintain the efficiency of electrical systems. Their design minimizes maintenance efforts and maximizes space utilization.

Selecting an appropriate SPD depends on factors such as application type and voltage protection requirements.

Isolators disconnect electrical circuits completely when switched off. This stops any current from reaching the load side, even during sudden voltage impulses. They help manage circuits safely during faults, maintenance, or normal operation across homes, offices, and industrial setups.

An isolator opens the circuit to stop current flow. It is built to make, carry, and break current based on the system’s needs. This makes it a vital part of electrical protection and control.

Isolators come with practical features for safe use and flexible installation. The Exora range includes a quick break mechanism, true contact position indicator, and energy limitation class 3, which add safety and help reduce energy use. The Tripper range is built with home safety in mind and supports a secure living environment.

The right selection of the isolator improves safety and supports smooth electrical control.

Distribution Boards divide electrical power into separate circuits and provide protective enclosures for each one. They support structured wiring and controlled circuit access across residential, commercial, and industrial applications.

A Distribution Board receives the main electrical supply and channels it into multiple smaller circuits. Each circuit includes protective devices such as MCBs or RCCBs. This setup allows for better power management and quicker response to faults without disturbing the entire system.

They are used in homes to manage circuit-level control for appliances and lighting. In commercial spaces, they help distribute power to office equipment, lighting systems, and HVAC. In industrial setups, DBs organize and control power for machinery and tools for improving safety and operational control.

A well-selected DB improves circuit organization and enhances safety. Consider both technical specifications and site conditions while selecting one.

Motor Protection Circuit Breakers (MPCBs) and Molded Case Circuit Breakers (MCCBs) protect against overloads, short circuits, and phase imbalances. While MPCBs are designed specifically for motor protection, MCCBs offer broader application coverage in power distribution systems.

MPCBs and MCCBs function by detecting abnormal electrical conditions and disconnecting the circuit before damage occurs. MPCBs offer motor-specific thermal and magnetic protection, enabling efficient performance and simple startup.

These breakers are critical for electrical safety and system reliability in various applications.

Selecting the right breaker depends on system requirements and application needs.

Add-on blocks enhance the capabilities of electrical devices by enabling additional control, protection, and monitoring functions. These modular accessories integrate with circuit breakers, contactors, and relays, providing flexibility for customized electrical configurations.

.jpg)

Designed to attach directly to primary devices, add-on blocks extend their operational features without altering the core system. They can provide auxiliary signaling, remote operation, or extra protection layers in electrical installations.

Add-on blocks are essential in expanding system functionality across various applications.

Selecting the right add-on block depends on its intended function and compatibility.

FN switches offer electrical systems protection, isolation, and safe circuit switching. They make it possible to safely cut off power, avoiding unintentional operation and guaranteeing system dependability in industrial settings.

.jpg)

FN switches function as manual disconnect devices, offering a clear ON/OFF control for electrical circuits. They isolate equipment during maintenance, ensuring worker safety and preventing unintended power flow.

FN switches are widely utilized in various electrical control and safety applications.

Choosing the appropriate FN switch depends on system requirements and safety standards.

Copyright © 2025 All Rights Reserved By KB Enterprises | Developed By Smart Stream Technologies